NPK Dry Powder Fertilizer Roller Press Granulator

Usage: Production of npk compound fertilizer granules

Production capacity: 1-3t/h

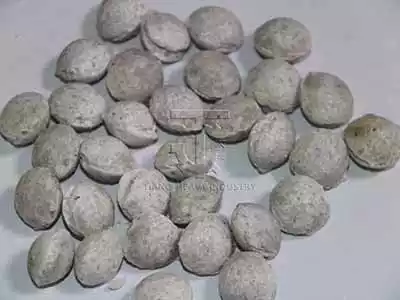

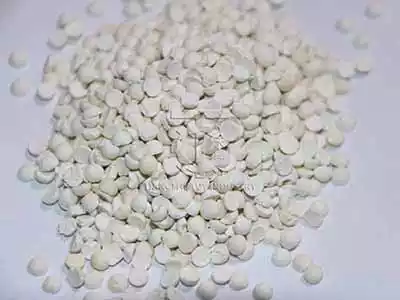

Granules Diameter: 2-20mm

Granular Shape: Oblate or irregular

Applicable Raw Materials: Chemical dry powder

The exhibition will be held in March 17-19, 2025 at the National Convention and Exhibition Center (Shanghai), our company’s booth is located in Hall 8.2, No. 49 (82B49), our company carefully prepared a lot of exhibits, not only advanced double roller press granulator machine, disc granulator machine and other granulation equipment, there are a number of automatic fertilizer production line models, as well as a variety of finished granules.

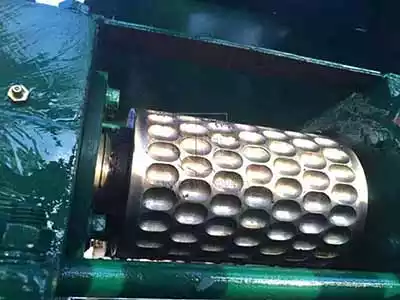

The structure of roller press granulator adopts granulation, forming and screening as a whole, which makes it have the characteristics of simple operation and low energy consumption.

The machine has wide adaptability to raw materials, such as Potassium chloride powder, iron powder, mineral powder, graphite powder, NPK powder, ammonium sulfate powder, urea powder, bentonite, etc

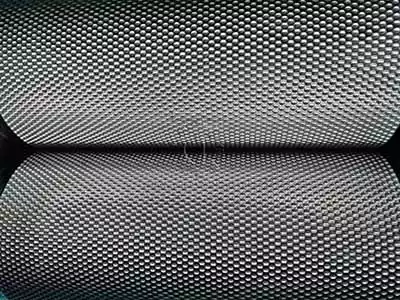

According to different diameter of roller, you can choose different shapes and diameter of granules.

Different roller skins can produce granules of different shapes and sizes.

This series of roller press granulators comes in multiple models, which can be selected according to the production needs of users or customized. The main technical parameters are shown in the table below:

| Model | DZJ-Ⅰ1.0 | DZJ-Ⅰ2.0 | DZJ-Ⅰ3.0 | DZJ-Ⅰ4.0 | DZJ-Ⅱ1.0 | DZJ-Ⅱ2.0 |

| Production Capacity(t/h) | 1~1.5 | 1.5~2.5 | 2~3 | 3~4 | 1~2 | 1.5~2.5 |

| Power(kw) | 15KW | 18.5KW | 22KW | 30KW | 15KW | 18.5KW |

| Pressure roller size | Φ150×220 | Φ150X300 | Φ186X300 | Φ300X300 | Φ150X220 | Φ150X300 |

| Feeding size | ≦0.5mm | ≦0.5mm | ≦0.5mm | ≦0.5mm | ≦0.5mm | ≦0.5mm |

| Finished product specifications | Φ2.5~Φ10 | Φ2.5~Φ10 | Φ2.5~Φ20 | Φ2.5~Φ30 | Φ2.5~Φ10 | Φ2.5~Φ20 |

| Material moisture | 2%~5% | 2%~5% | 2%~5% | 2%~5% | 2%~5% | 2%~5% |

1-20t/h NPK compound fertilizer production line with roller press granulator (taken from our old customers):

Package : wooden package or full 20GP/40HQ container

Create a simple and convenient service experience for you anytime, anywhere.