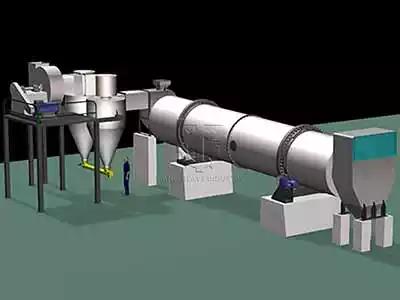

Fertilizer rotary dryer

Usage: Drying of organic fertilizer and compound fertilizer

Production capacity: 1-30t/h

Intake Temperature : ≥300℃

Rotary Speed: 3-5 r/min

Heat Source: Coal, natural gas, liquefied gas, methanol, biomass

Applicable materials: Poultry manure, Coal slime, lignite, mineral powder, slag, ore, distiller’s grains, sawdust, pomace, bean dregs, sugar residue.